Laser Cut Stainless Steel Christmas Ornament

Every year our laser shop @ RiverCity Industries holds an employee contest for the best Christmas ornament. Last year our Tube Laser won it, this year’s winner goes to our flat bed Fiber Laser operators!

Every year our laser shop @ RiverCity Industries holds an employee contest for the best Christmas ornament. Last year our Tube Laser won it, this year’s winner goes to our flat bed Fiber Laser operators!

Our principal – RiverCity Industries has just launched their new website at www.rivercity-industries.com

RiverCity delivers laser cut metal and laser cut tubing all over Texas with their own fleet of 18 wheelers.

RiverCity Industries’ mission is to be a one stop turn-key fabrication facility with a focus on precision laser metal cutting in both flat sheet and tube laser parts.

*Please note that our CNC Laser & Press Brake combo works great for 3D CAD models. We have CAD designers on staff to take your 3D CAD designs and convert to our machine language.

6’ x 12’ table size

1/2” max on Aluminum for a “Clean Edge” – could go to ¾” with slightly rougher edge.

1/2” max on Copper for “Clean Edge”– could go to ¾” with slightly rougher edge.

1/2” max on Brass for “Clean Edge”– could go to ¾” with slightly rougher edge.

Fiber Laser technology is new and we just installed the first US BLM Fiber laser. Not only is the fiber laser up to 10 times faster than traditional lasers, it cuts with much better edge quality. Not that our old lasers have poor edge quality, it’s just that the fiber performs better in problematic metals like Aluminum and stainless steel, where reflectivity and heat buildup cause issues. Our new fiber laser can cut through 1″ carbon, 3/4′ ” aluminum and stainless and 1/2″ aluminum and stainless steel with superior edge quality. It will even laser cut copper and brass material up to 1/2″ thick.

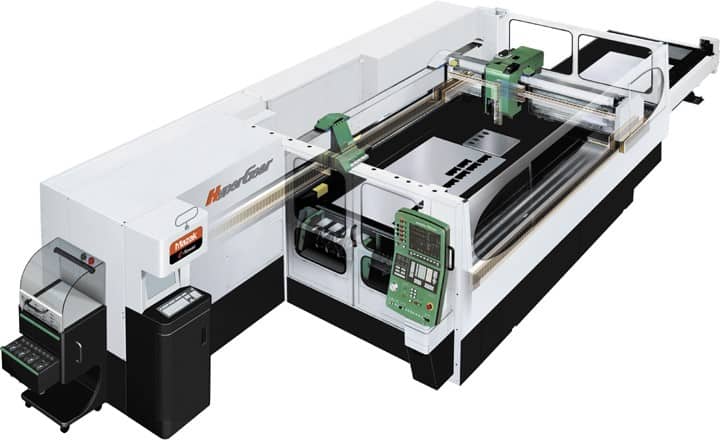

Laser Cutting 4,000W HyperGear:

Features: Dual shuttle tables, automated nozzle, and torch change. Focus adjustments for more efficient cutting and flexibility to cut different material types and thicknesses per shift.+/-.004” accuracy. Nesting software for maximum sheet yield.

Features: Dual shuttle tables, automated nozzle, and torch change. Focus adjustments for more efficient cutting and flexibility to cut different material types and thicknesses per shift.+/-.004” accuracy. Nesting software for maximum sheet yield.

5’ X 10’ table size

¼” max on Aluminum

Cutting in 3D on various off the shelf tube sizes, angles and other structural dimensions is a breeze with the Mazak U44. It cuts stainless, aluminum and carbon steel.

Our new ADIGE LT-8 Laser cutting large, heavy wall metal tubes. 3D angles for better welding fit up, coping, chamfers, slot and tab fixturing. Large and thick wall tubes to be welded or for joints or couplings requiring precision. Making special, open, concave and asymmetric sections in round tubing, square tubing and structural tubing.

LT-8 Specs

Steel 5/8″ wall thickness

Aluminum 1/4″ thick

Stainless Steel 3/8″ thick

Large Format Tube Laser, Cuts Through 5/8″ wall thickness on 8″ diameter round tube & 6″ square tubing.

The large magazine holds up to 20 foot lengths at high production quantities of tube and pipe.

3D Tube laser cutting fish mouth coping on 5.5″ Stainless Steel tubing. The laser was CNC programmed to cut at precise angles for the weld bead and a nice coped fit to a matching leg on industrial food processing equipment. Try that with a torch!

Trade show exhibits for our RiverCity Industries principal. This is our 5th year to exhibit at Houstex. Showing off Laser metal cutting in Houston Texas at the George R. Brown convention center. This year we were honored to arrange for our Greater Houston Manufacturing Association www.houston-mfg.com to get a booth courtesy of our partner Society of Manufacturing Engineers. Thanks to all of our customers and new prospects that came by to visit – it was a fantastic show!

* We selected a booth space adjacent to an open area in the show floor plan. It was nice to see that they filled that space with a yellow convertible Ferrari – that was a real show stopper and right across the aisle from our booth!

Our Lasers cut these 1/2″ plates smoothly and efficiency – saving our customer money by eliminating the need for secondary processes. Our welding department completed the assembly turn key.