Lots of cool technology at this show, it’s actually a machine shop equipment show, but we have always done well there showing off our fabrication services. Thank you Houston!

Fabrication Sub-Assembly For Equipment Manufacturers

Equipment manufacturers all over Houston rely on us to fabricate sub-assemblies for just in time inventory. Lean manufacturing dictates subcontracting to fabricators like us in order to get more production out the door. For this same reason, we welcome overflow work from other fabricators and equipment manufacturers – even those who have in-house capabilities.

Many equipment manufacturing companies have in-house capabilities for metal fabrication of the sub-assembly. However, many find that welders and electricians don’t make for a good combination under the same roof. Welding is dirty business and electrical control panels, require a clean environment.

Our trucks roll all over Houston – Let us help you with your fabricated sub-assembly work.

Centrifuge Base Fabrication for Decanter & Dewatering Units

Equipment manufacturers appreciate our Mid South Fabrication principal’s unique ability to machine large horizontal centrifuge bases to tolerance “after” fabrication – all in house.

The pillow blocks on the centrifuge base require tolerances close to the .010″ range. On a large fabricated base, that is impossible to achieve unless you can machine it after you fabricate it. We have a large format horizontal mill capable of holding 20,000 pounds and 118″ inched of horizontal travel. It makes quick work of machining to tolerance “after” fabrication.

All of the fracking going on in the oilfield these days requires a ton of water treatment. Horizontal centrifuges can dewater and separate the solids quickly and efficiently. Solids control conserves our precious water supply by recycling the drilling mud and fracking fluid.

- Large Centrifuge Base on it’s side – Pillow blocks facing the mill

- Decanter Centrifuge – pillow blocks milled after fabrication

- Large Horizontal Mill

Representing T-REX Engineering & Construction

T-REX Engineering and Construction has a long history of advanced fabrication in the Houston and GoM region. Specializing in complex SubSea fabrication and Offshore fabrication as well as onshore projects, including engineering, construction drawings, and design. T-REX has 31 years experience, located on 33 acres with quayside facilities on the Houston Ship channel. No project is too big for T-REX…

ASME U and NBBI R Stamp stamps qualify us to build, modify or repair Boilers, Pressure Vessels + Pressure Relief devices. This includes designing High Pressure Piping Systems offshore to 20 KSI.

Call 713-401-3007

Offshore Fabrication At Its Best – OTC 2014

Proud to see our fabricated projects on display at OTC this year. The Offshore Technology Conference in Houston was another technical marvel. Once again – Pushing metal fabrication and design to the limits. They say as much, if not more technology goes into Engineering, Design, Fabrication and Construction for offshore projects as goes into outer space! We believe it! Another great year at OTC!

Offshore Technology Conference and SubSea Fabrication

Looking forward to meeting our customers at the Offshore Technology Conference next week. Excited to see the latest developments in subsea and offshore fabrication. We’re thinking GOM and Mexico will be a hot topic.

Houston Fabricated Enclosures & Generator Skids

We never know what kind of enclosures Houston manufacturers will ask us to fabricate. We can laser cut, bend, weld and paint just about any enclosure you need with precise, repeatable accuracy. Whether it be accommodations for an offshore platform, a generator enclosure, a control panel, or a belly box for an 18 wheeler. We even make enclosures for Wellheads. Some enclosures come on skid frames like the mud tanks and genset skids we fabricate – all turnkey and delivered on our fleet of trucks.

- By Ken Doerr from Chester, UK (http://creativecommons.org/licenses/by/2.0)

Offshore Fabricated Structures & the DNV

We’re winning more and more offshore fabrication for our Mid South Fabrication principal. Right now we have a project in-house for umbilical reel frames to be mounted on drill ships.

Of course weld procedures used on anything fabricated for offshore applications have to be certified by the DNV. Mid South Fabrication is no stranger to developing welding procedures to our client’s welding specifications. We’re a code weld shop for heavy structural welding to AWSD1.1 standards, including ASME and National Code Welding – R, S, U, NB. From pressure vessel and high pressure pipe welding witnessed and certified by Hartford Steam Boiler to the DNV – we work with all classification societies in developing our weld procedures.

For these umbilical reel frames, our EPC client needed us to perform to their own inhouse weld procedure, and witnessed by the DNV.

Fabricated Structures for Offshore Oil and Gas

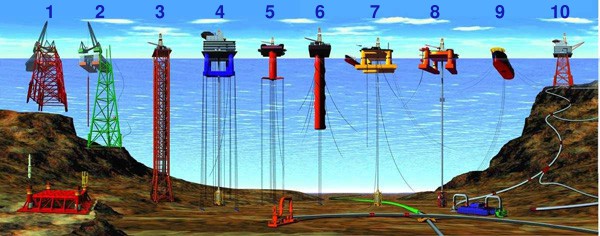

1) & 2) Conventional fixed platforms (deepest: Shell’s Bullwinkle in 1991 at 412 m/1,353 ft GOM)

3) Compliant tower (deepest: Chevron Texaco’s Petronius in 1998 at 534 m /1,754 ft GOM)

4) & 5) Vertically moored tension leg and mini-tension leg platform (deepest: ConocoPhillips’ Magnolia in 2004 1,425 m/4,674 ft GOM)

6) Spar (deepest: Dominion’s Devils Tower in 2004, 1,710 m/5,610 ft GOM)

7) & 8) Semi-submersibles (deepest: Shell’s NaKika in 2003, 1920 m/6,300 ft GOM)

9) Floating production, storage, and offloading facility (deepest: 2005, 1,345 m/4,429 ft Brazil)

10) Sub-sea completion and tie-back to host facility (deepest: Shell’s Coulomb tie to NaKika 2004, 2,307 m/ 7,570 ft)

Source: NOAA – Numbered from left to right; all records from 2005 data

Det Norske Veritas (DNV) recently merged with the classification society Germanischer Lloyd to form DNV GL. In order to certify to our client’s weld procedure, first we will send the welding and testing specifications to a DNV welding engineer. Once approved, a DNV surveyor will do a site visit to witness the welding of two test coupons, using the exact brand of welding wire, amperage, and speed – as dictated in the client’s weld procedure. Then one of the test coupons will be sent sent to a lab for a secondary DNV surveyor witness on destructive and nondestructive examination and analysis.

Our Trucks Roll All Over Texas Delivering Metal Fabrication JIT

We like to be in control. That’s why our metal fabrication partners handle everything in house. Fabrication, Paint, Machining, and Delivery. We have regular truck routes, on our own fleet between Houston, Dallas, San Antonio, Austin, and West Texas. Much of our work involves sub-assemblies and overflow work, so timing is critical for our customers.

The Natural Gas Boom is Driving More Big Fabrication & Skid Packages

Our Mid South Fabrication partner continues to add heavier equipment as our sub assemblies and skids continue to grow in scale with increased demand from natural gas customers. We recently added a another 10 ton crane to work in tandem flipping large gas compression plant skid bases filled with concrete! Large Lathe added to our machining division, enables us to machine to tolerance “after” fabrication of large assemblies. Fracking continues to drive our frack tank panel business.

- Gas Compression skids being coated in our large capacity paint booths

- Gas Compression skids being coated in our large capacity paint booths

- Skid frame Sub Assembly

- Offshore fabricated skid sub assembly

- Long Bed Lathe

- Big Lathe

- Frack Panels

- Concrete Filled Skids

- Fabricated Tanks