We’re winning more and more offshore fabrication for our Mid South Fabrication principal. Right now we have a project in-house for umbilical reel frames to be mounted on drill ships.

Of course weld procedures used on anything fabricated for offshore applications have to be certified by the DNV. Mid South Fabrication is no stranger to developing welding procedures to our client’s welding specifications. We’re a code weld shop for heavy structural welding to AWSD1.1 standards, including ASME and National Code Welding – R, S, U, NB. From pressure vessel and high pressure pipe welding witnessed and certified by Hartford Steam Boiler to the DNV – we work with all classification societies in developing our weld procedures.

For these umbilical reel frames, our EPC client needed us to perform to their own inhouse weld procedure, and witnessed by the DNV.

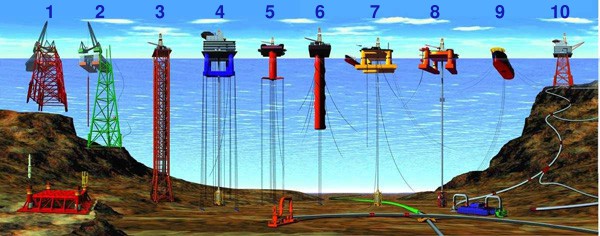

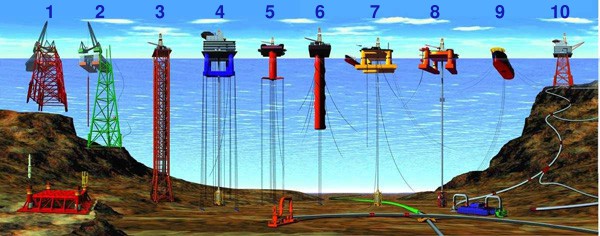

Fabricated Structures for Offshore Oil and Gas

1) & 2) Conventional fixed platforms (deepest: Shell’s Bullwinkle in 1991 at 412 m/1,353 ft GOM)

3) Compliant tower (deepest: Chevron Texaco’s Petronius in 1998 at 534 m /1,754 ft GOM)

4) & 5) Vertically moored tension leg and mini-tension leg platform (deepest: ConocoPhillips’ Magnolia in 2004 1,425 m/4,674 ft GOM)

6) Spar (deepest: Dominion’s Devils Tower in 2004, 1,710 m/5,610 ft GOM)

7) & 8) Semi-submersibles (deepest: Shell’s NaKika in 2003, 1920 m/6,300 ft GOM)

9) Floating production, storage, and offloading facility (deepest: 2005, 1,345 m/4,429 ft Brazil)

10) Sub-sea completion and tie-back to host facility (deepest: Shell’s Coulomb tie to NaKika 2004, 2,307 m/ 7,570 ft)

Source: NOAA – Numbered from left to right; all records from 2005 data

Det Norske Veritas (DNV) recently merged with the classification society Germanischer Lloyd to form DNV GL. In order to certify to our client’s weld procedure, first we will send the welding and testing specifications to a DNV welding engineer. Once approved, a DNV surveyor will do a site visit to witness the welding of two test coupons, using the exact brand of welding wire, amperage, and speed – as dictated in the client’s weld procedure. Then one of the test coupons will be sent sent to a lab for a secondary DNV surveyor witness on destructive and nondestructive examination and analysis.