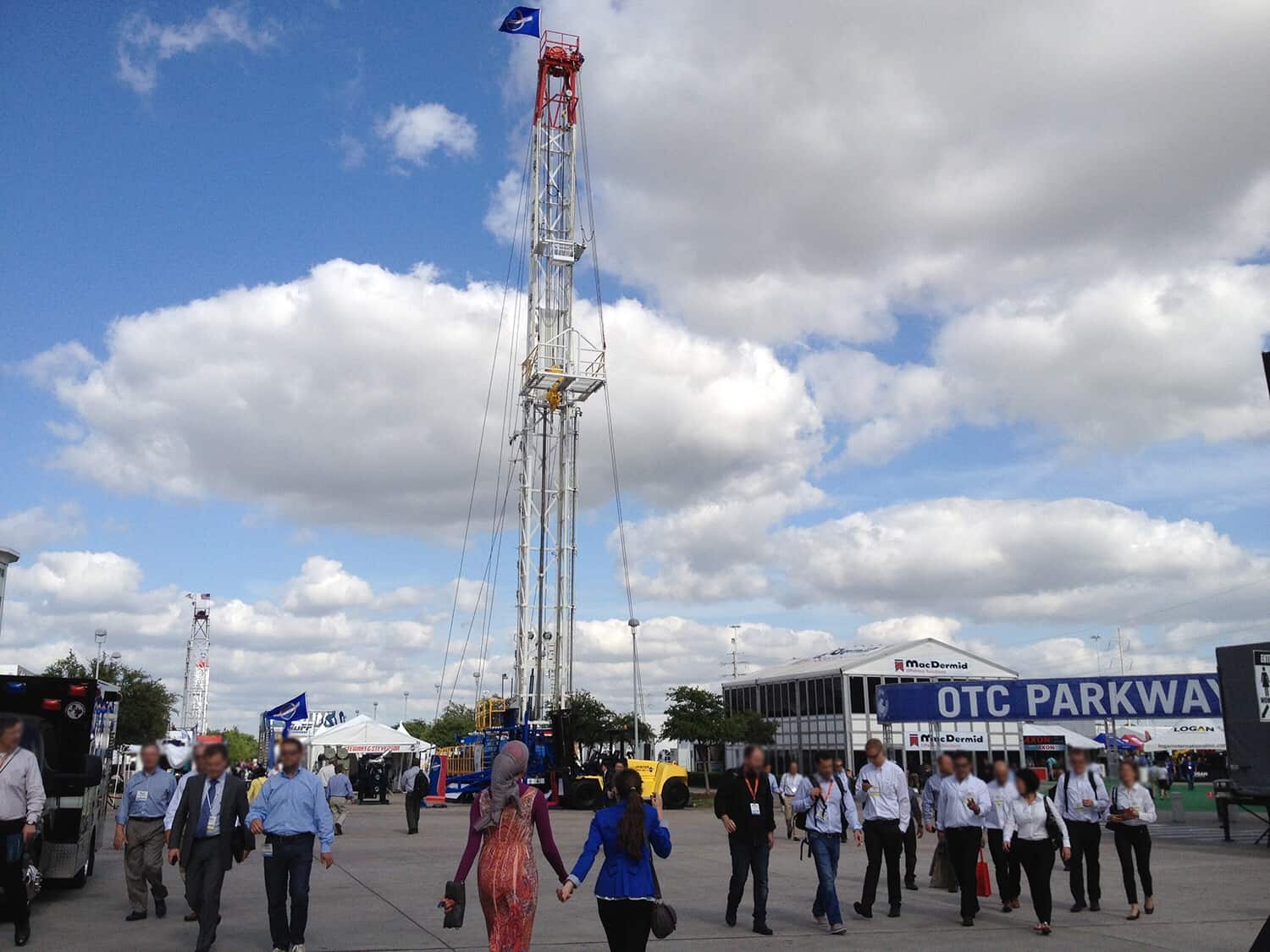

Your Houston Piping Fabricators

Our principals can fabricate, weld, bend and laser cut pipe. Ocean Fab is your one stop fabrication source for all of your welded and fabricated piping needs.

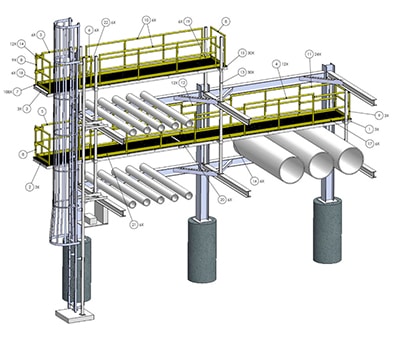

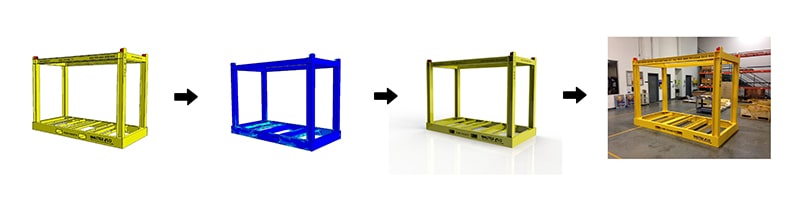

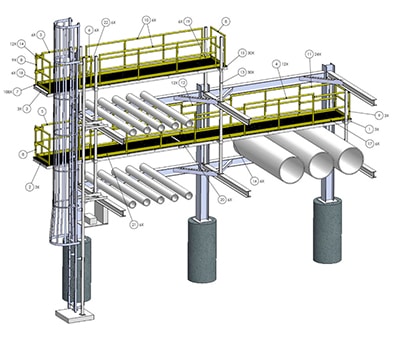

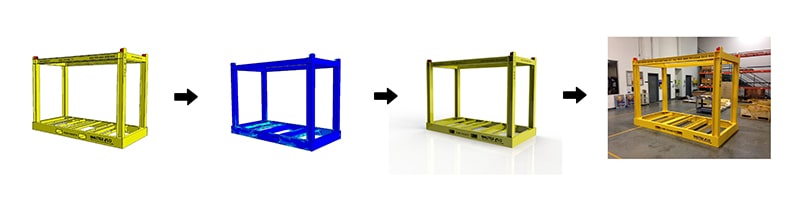

It’s one thing to be able to fabricate a plain old steel frame for an equipment skid. Any fab shop can do that… It’s a whole other thing to be able to complete a piping system, fabricating the pressure piping and other critical components that are required on a process skid.

Our fabrication principals offer our OEM manufacturers turnkey solutions for their piping sub-assemblies with ASME certification stamps R S and U to complete your project, including NACE certification for the final painting and coating – and even final delivery with our in-house fleet of 18 wheelers.

Our fabrication principals offer our OEM manufacturers turnkey solutions for their piping sub-assemblies with ASME certification stamps R S and U to complete your project, including NACE certification for the final painting and coating – and even final delivery with our in-house fleet of 18 wheelers.

We carry over 50 approved welding procedures and the most stringent certifications available for anything from High pressure piping – to DNV and ABS certification. Our ASME code stamps, R Stamp, U Stamp and S Stamp. AWS D1.1 – API 6A … and many other certifications assure our customers of quality and compliance with industry standards.

Our certifications allow you to have a “one stop fabrication shop” who can design, construct, or repair equipment skids containing piping to pressure vessels and other components typically found on OEM manufacturer’s process skids.

From small diameter piping .5″ up to 72″ and High pressure up to 25,000 PSI.

Providing NDE X-Ray and Mag Particle testing.

Our Typical Pipe Fabrication Products

- Buffer Chambers

- Choke Manifolds

- Manifold Assemblies

- Standpipe Manifolds

- Plug Valves

- Mud Pumps

- Pipeline

- Suction Manifolds

- Discharge Manifolds

- Pipe Flanges

- Choke and Kill pipe component fabrication

- Chemical Plant and Refinery Piping for the Petrochemical Industry

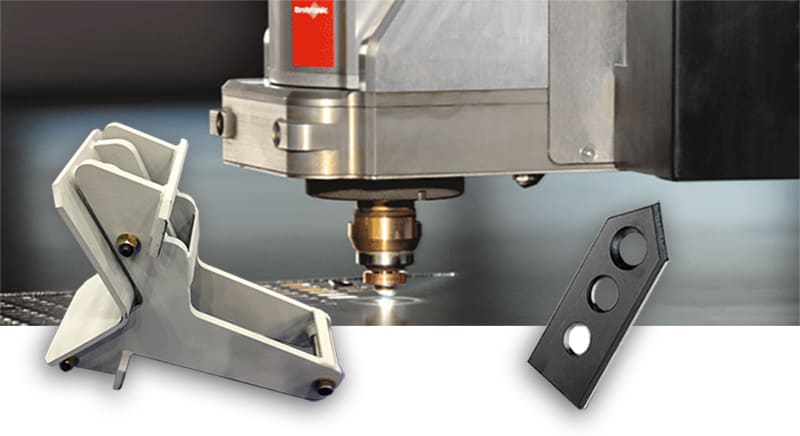

- Laser cut and bent Tubular Parts for the furniture industry

- Laser cut Perforating Gun – Charge Carrier Tubes